DS4U is officieel importeur WINNO ENERGY ,

Experts in Biomass and Waste to Energy industry TECHNOLOGY / DESIGN / UPGRADE

Experts in Biomass and Waste to Energy industry

Experts in Biomass and Waste to Energy industry TECHNOLOGY / DESIGN / UPGRADEBEST BIOMASS AND W2E PLANTS FROM WINNO ENERGY

Winno Energy has many years of experience in designing and supplying a wide range of biomass boiler plants.

WHY BIOMASS OR WASTE COMBUSTION?REDUCE ENERGY COSTS BY UP TO 50%REDUCE YOUR WASTE DISPOSAL COSTSPROTEC YOURSELF FROM INCREASING ENERGY PRICESREDUCE YOUR CARBON FOOTPRINTSIMPLE INTEGRATION WITH EXISTING HEATING SYSTEM

JOIN THE BUSINESSES ALREADY BENEFITTING FROM THEIR BIOMASS AND WASTE COMBUSTION BOILERS

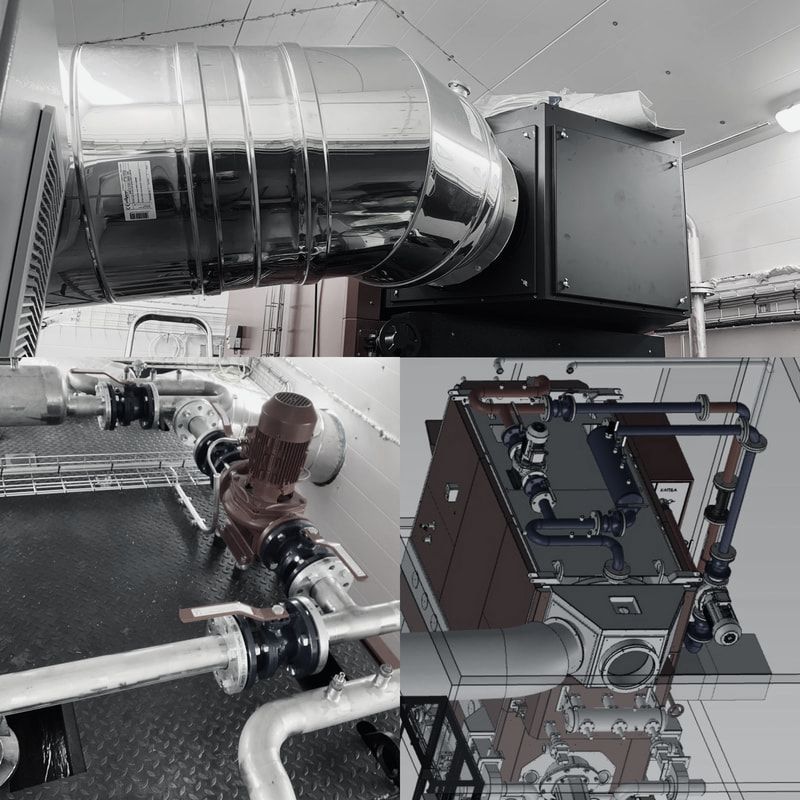

In the Europe and North America a biomass boiler burns logs, pellets or wood chips, and is usually connected to a central heating and/or hot water system in much the same way as a standard gas or oil boiler would. Our approach to switch to renewables: Site visit, calculate size of biomass replacement plant and fuel evaluatoinProposal of most suitable biomass plant designConfiguration that meets heat demand and emission limitsManufacturing & waste/biomass plant delivery to client siteInstallation with our biomass and waste boiler plant installation partnersWinno Energy not only supplies boiler plants in a range of sizes and variants, we also have vast experience in this sector and ability to design and configure biomass plants that match your requirements and fully comply with design standards.

What is the biomass fuel Biomass is plant or animal material used for energy production (electricity or heat), or in various industrial processes as raw material for a range of products. [1] It can be purposely grown energy crops (e.g. miscanthus, switchgrass), wood or forest residues, waste from food crops (wheat straw, bagasse), horticulture (yard waste), food processing (corn cobs), animal farming (manure, rich in nitrogen and phosphorus), or human waste from sewage plants. [2]Burning plant-derived biomass releases CO2, but it has still been classified as a renewable energy source in the European Union and United Nations legal frameworks because photosynthesis cycles the CO2 back into new crops. In some cases, this recycling of CO2 from plants to atmosphere and back into plants can even be CO2 negative, as a relatively large portion of the CO2 is moved to the soil during each cycle.Winno Energy is one of the most innovative technology supplier in the biomass field and we would like to turn that material into valuable fuel source which will reduce CO2 emission footprint.

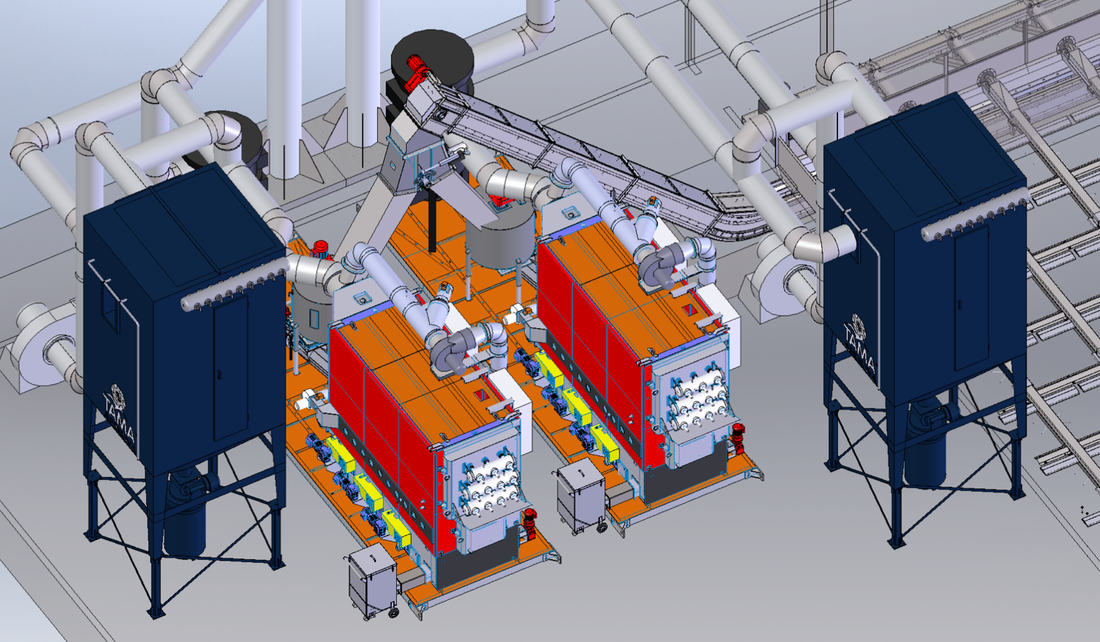

WID COMPLIANT WASTE WOOD BIOMASS AND RDF COMBUSTION PLANTS

We have got WID compliant boilers for the C grade waste wood and SRF combustion

Our WID compliant waste wood gasification boiler manufacturer has over 60-years experience. Works with really low-quality wood, MDF, and chipboard based biomass, and waste wood SRF combustion is possible together with biomass (80/20% ratio) Waste wood combustion is more than two seconds 850-degree gasification combustion process. (This is important because grate firing struggles to meet two seconds 850-degree combustion) Boiler power range: 8%-100% (During summer months boiler can run nicely with low heat demand and it accelerates nicely when the boiler is already running) If there are power cuts boiler can start itself automaticallyAsh handling is wet ash handling and made from acid resting steel Flue gas dust content within the boiler is only circa 50 mg/nm3, keeping the boiler clean The boiler needs to be cleaned only once a year as part of its annual maintenance. Smoke gas channels are acid resting steel. When commissioning is finished we can make onsite testings before last payment as our gasification boilers have emission guarantees.

Key specifications for our waste wood boilers:

Output: 0,5MWth to 10MWth

Temperature range: 110-180°C

Pressure: 4, 6, 10 or 16 bar

Fuels: Biomass and co-incineration with SRF waste.