Bioenergy production has become an increasingly popular source of renewable energy in recent years. Utilizing organic material, bioenergy plants are able to provide a steady, reliable stream of energy with minimal environmental impact. As these plants become more and more common, the need for advanced upgrades and services has increased. This article will discuss the importance of bioenergy plant upgrades and services, and emphasize the need for continual maintenance and proper upkeep.

Bioenergy Plant Basics

Bioenergy plants are designed to convert organic matter such as wood chips, agricultural waste, and manure into energy. The process involves the use of anaerobic digestion or gasification techniques to break down the material and produce a combustible biogas. This biogas is then combusted in a turbine or engine to generate electricity, heat, and steam.

When considering upgrades and services for bioenergy plants, it is important to consider factors such as efficiency gains from upgraded components, reliability of equipment and systems, emissions reduction potentials from improved combustion processes, increased safety measures through better monitoring equipment, and cost savings through optimized operations. Upgrading controls can also improve the operator’s ability to manage the plant more efficiently while ensuring compliance with regulations. In addition to these upgrades and services, maintenance needs should be assessed regularly to ensure that all components are functioning properly and operating at peak performance levels.

Types of Upgrades: Efficiency & Emissions

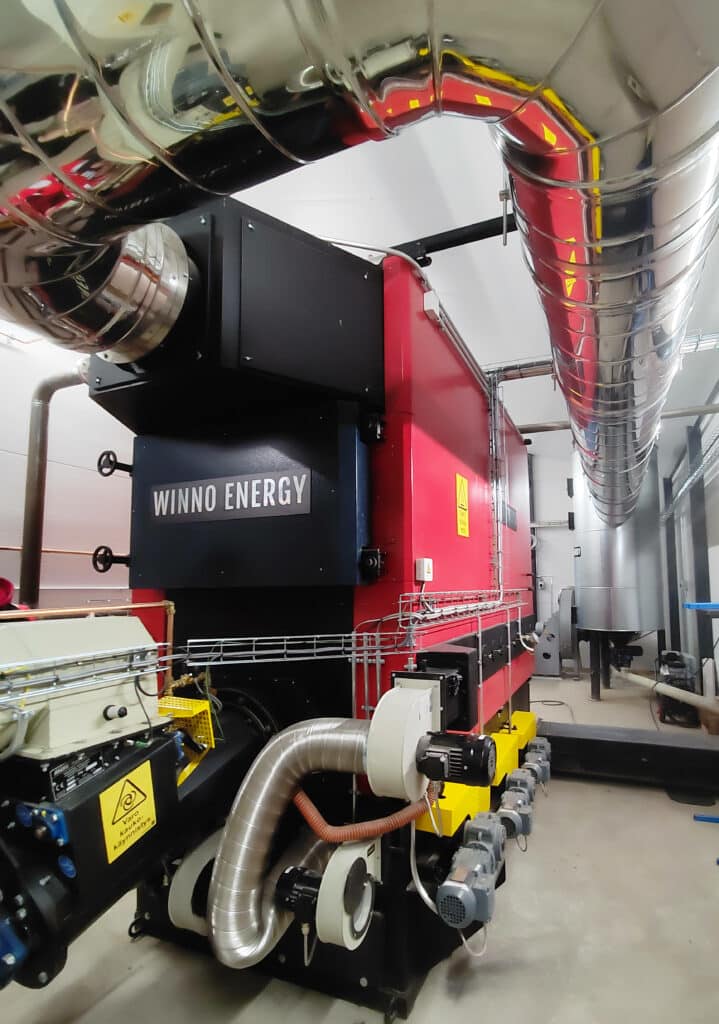

Efficiency upgrades can increase the productivity of a bioenergy plant and lower its operating expenses. This can be achieved through installing new equipment, improving processes, or changing the way resources are used. Examples of efficiency upgrades include updating boilers to reduce heat losses, optimizing combustion processes to improve fuel efficiency, and replacing worn parts to reduce downtime.

Emissions upgrades are a key aspect of environmental compliance and protection. These may involve adding scrubbers or filters to capture particulate matter or emissions control systems that remove pollutants from exhaust gas streams. Additionally, measures such as process optimization and switching fuels can help reduce emissions while maintaining efficiency. By upgrading these systems, bioenergy plants can minimize their environmental impact while achieving better energy performance.

In Winno Energy we can upgrade plants to meet medium plant combustion directive emission limits (MPCD).